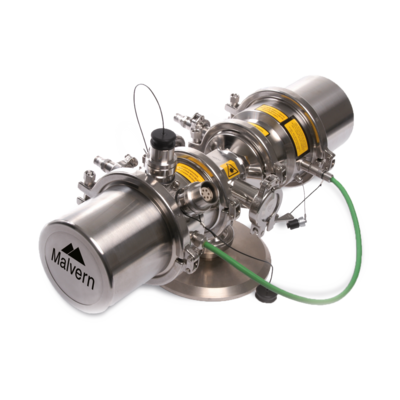

Insitec Spray

The industrially robust, technologically proven process particle size analyzer for sprays and aerosols

- Measurement range from 0,1 to 2.500 µm

- Robust, reliable aerosol and spray particle measurement

- Available for standard, pharmaceutical processes and gas or dust zoned hazardous environments

- Base model hardware manufactured to GAMP5 standards and compatible with CIP/SIP requirements to meet specific manufacturing specifications

- High reliability of >95% with little downtime, minimal maintenance and maximum ROI

Engineered to withstand the rigors of the process environment, Insitec Spray uses laser diffraction technology to measure droplets and dry particles from 0,1 µm to 2.500µm. Capable of measuring even highly concentrated sprays and aerosols, Insitec Spray delivers real-time monitoring and control, 24/7. Flexible configuration simplifies installation on the process with options for:

•Fully customized configuration

•Powder streams

•Pharmaceutical processes

Insitec Spray particle size analyzers deliver fully automated, in situ, real-time particle size measurement for sprays and aerosols. They are used to monitor conditions in wind tunnels and atmospheric chambers, to characterize domestic aerosols and personal care products, and to monitor batch and continuous processes such as spray drying.

| Measurement type | Particle size |

| Measurement range | 0.1 to 2500µm |

| Measurement principle | Laser diffraction |

| Optical models | Mie theory |

| Accuracy | ±2% on Dv(50) reported using the verification reticle |

| General Power | 100/240V |

| Enclosure rating | IP65 |

| Operating platforms | 10 bar (g) |

| Software | RTSizer (for instrument control) Malvern Link II (for system automation and data link) |

| Maximum distance from instrument to PC | 500m (up to 2 km using fiber optics) |

| Operating environment Temperature | 10°C - 70°C |

| Humidity | 35% - 80% (non-condensing) |

Sysmex Nederland B.V.

Ecustraat 11

4879 NP Etten-Leur

The Netherlands

+31 (0)76 508 6000

+31 (0)76 508 6086

Sysmex Belgium N.V.

Chaussée de Bruxelles 135A

1310 La Hulpe

Belgium

+32 (0)2 769 7474

+32 (0)2 7697499

![[.NL-en Netherlands (english)] [.NL-en Netherlands (english)]](/fileadmin/_processed_/2/b/csm_MP_Insitec_Spray_f3ec9e09b2.png)

![[.NL-en Netherlands (english)] [.NL-en Netherlands (english)]](/fileadmin/_processed_/2/b/csm_MP_Insitec_Spray_71a59d8021.png)